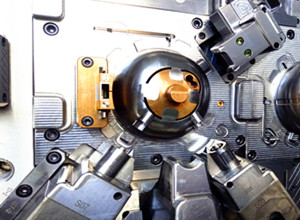

MOULD MANUFACTURING

Expert Plastic Injection Mold Manufacturing Since 2012

Mold manufacturing is where Heran began, it remains one of our core competencies.

We specialize in tight-tolerance, custom molds, from single cavity prototypes to large multi-cavity production

molds up to 15,000 lbs. Whether you provide approved mold designs or you work with our experienced

team to develop the tooling designs you require, we will ensure the best mold is built for your intended application.

Using state-of-the-art mold design and building TECH, we offer mold manufacturing for the following types of tooling:

√ Conventional custom plastic molds

√ Precision injection moulds

√ Insert molding tools

√ High cavitation injection molds

√ Two Shot molds / 2K molds/ Bi-injection moulds

√ Unscrewing molds

√ Gas assist moulds

√ Special structural moulds

√ Thermoset molds

√ Die casting tools

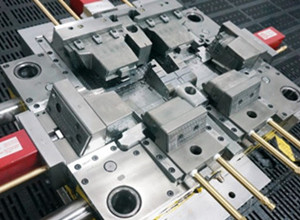

Capacity: √ 15-20 sets per month √ Typical lead-time for T0: 4-6 weeks, depending on the producttype/complexity.

Our in house tool room, we believe, is one of the most important factors that sets us apart from many others. Having a tool room in the same facility has several advantages

√ You are able to work with the same people "From Conception to Completion", reducing lag time in communication between suppliers, and eliminating the "Blame Game" often played when working with multiple companies.

√ The people building the tooling are the same people putting it into production. That way you know that the plastic injection mold life will be designed to coincide with the life of your product, and built with the best material and workmanship available in your price range, because we have a vested interest in a mold that runs efficiently as well!

√ In house plastic injection mold making enables us to significantly reduce downtime and cost when problems arise in production,saving our Customers time and money.

Your mold will be designed and built by true craftsmen using CAD/CAM software, and CNC and EDM equipment. Our extreme attention to detail ensures that the plastic injection molds and our plastic injection mold making will meet or exceed your requirements.